Custom Coil Winding Solutions for Niche Industries

In the modern era of electrical engineering, precision and customization have become vital to product innovation. Whether for electric motors, transformers, or inductors, the efficiency and reliability of these components depend heavily on one essential process — coil winding. Manufacturers are now adopting custom coil winding machines to meet specific industrial requirements, ranging from heavy-duty transformers to compact electronic devices.

This article explores how customized coil winding technology is redefining production efficiency, the benefits it brings to niche sectors, and how advanced manufacturers such as Jiyu Drive by Wire and JSXL Machines are empowering industries through smart automation.

Understanding Coil Winding Machines

A coil winding machine is a specialized piece of equipment used to wind conductive wire (usually copper or aluminum) around a core to form a coil. These coils are the heart of countless electrical devices — from transformers and motors to inductors and sensors.

Depending on application size and complexity, manufacturers can choose from different machine configurations, such as:

-

Loop winding machines for large and medium-sized motor stator coils and transformer coils.

-

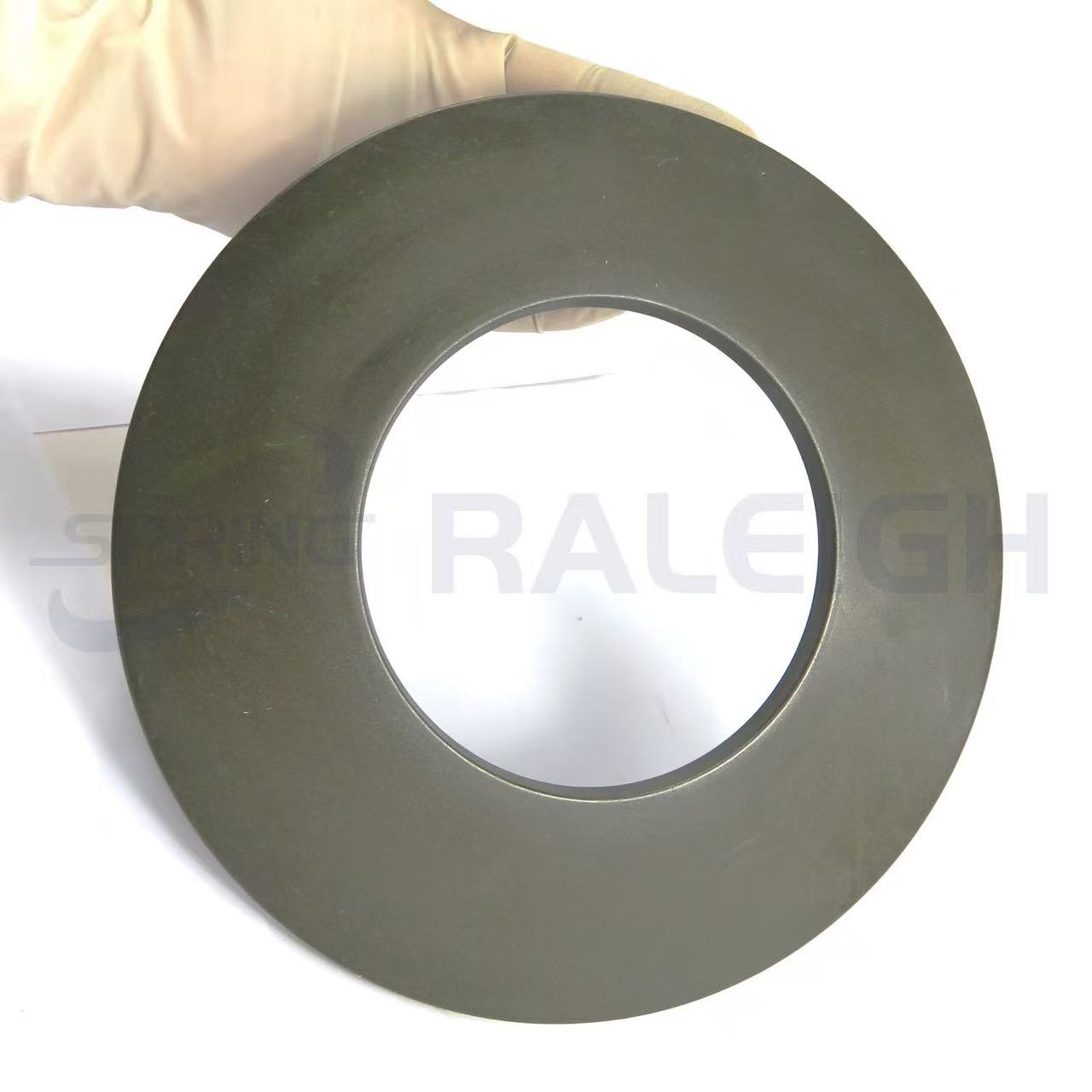

Toroidal winding machines for compact, high-frequency inductors.

-

Automatic winding machines that integrate servo control, tension monitoring, and programmable winding patterns.

These systems ensure high winding accuracy, consistent coil density, and minimal material waste — all critical factors for the performance and efficiency of modern electrical components.

The Shift Toward Customization

Traditional coil winding systems were once built for high-volume production of standard parts. Today, however, demand has shifted toward custom coil winding solutions that support specialized applications in fields such as:

-

Renewable energy systems, including wind turbine generators and solar inverters.

-

Aerospace and defense, where coils must perform under extreme conditions.

-

Automotive manufacturing, particularly in electric powertrains and drive-by-wire systems.

-

Medical equipment, requiring ultra-fine, high-precision coils for sensors and imaging.

Customization allows manufacturers to fine-tune parameters such as wire gauge, number of turns, winding tension, and layering pattern to match the exact functional and dimensional needs of each device.

Precision in Motion: How Advanced Machines Deliver Quality

Modern coil winding machines integrate servo motors, programmable logic controllers (PLC), and intelligent motion systems that guarantee micro-level accuracy. For example, loop winding machines designed for large transformer coils incorporate automatic layering, adjustable tension control, and error correction algorithms.

Such precision ensures:

-

Uniform coil distribution for optimal magnetic performance.

-

Reduced mechanical stress on the wire, improving durability.

-

Consistent insulation quality, which enhances safety and energy efficiency.

At the industrial level, this accuracy translates to reduced downtime, faster production cycles, and longer component lifespan — making advanced winding technology an essential part of modern manufacturing.

Applications Across Niche Industries

1. Electric Motors and Transformers

For large-scale power systems, loop winding machines from JSXL Machines are essential. They are specifically designed for producing stator coils and transformer windings, where stability and repeatability are non-negotiable.

2. Aerospace and Automotive Innovations

In fields like aerospace engineering and automotive electrification, the ability to produce compact yet high-performance coils is critical. Technologies such as drive-by-wire systems — exemplified by the Combat Wings W Series — rely on precise coil control within actuators and feedback sensors.

Customized coil winding ensures minimal electromagnetic interference and optimal signal transmission, which directly affects system responsiveness and safety.

3. Medical and Precision Electronics

Medical imaging devices, portable diagnostic tools, and precision sensors require micro coils with tolerances measured in microns. Custom winding machines allow engineers to precisely replicate intricate designs at scale, ensuring product consistency and compliance with strict industry standards.

Smart Automation: The Future of Coil Winding

Industry 4.0 is reshaping coil production with automation and digital integration. Modern systems now feature:

-

AI-based tension monitoring for adaptive control.

-

Data-driven quality inspection for defect detection in real time.

-

Remote programming and IoT connectivity for global process supervision.

By merging mechanical precision with intelligent software, manufacturers can now manage production across multiple product lines with minimal human intervention. This shift not only boosts efficiency but also significantly reduces human error in complex coil geometries.

Sustainability and Energy Efficiency

Another driving force behind custom coil winding solutions is sustainability. Optimized winding minimizes wire waste, reduces energy consumption, and improves overall transformer or motor performance.

For instance, advanced winding layouts lower electrical resistance and heat generation, which leads to longer component life and improved power efficiency — key goals for industries focused on green energy and carbon footprint reduction.

Choosing the Right Manufacturer

When investing in coil winding equipment, consider the following factors:

-

Customization Capability – The manufacturer should offer configurable models tailored to your coil type and production scale.

-

Precision Engineering – Look for servo-controlled systems with closed-loop feedback for maximum accuracy.

-

After-Sales Support – Reliable technical support ensures machine longevity and consistent performance.

-

Integration Flexibility – The system should easily interface with your production management and quality control systems.

Manufacturers such as JSXL Machines specialize in advanced loop winding machines for industrial applications, while Jiyu Drive by Wire demonstrates how precision winding directly enhances performance in intelligent actuation systems.

Conclusion

As industries evolve toward smarter, more efficient, and sustainable manufacturing, custom coil winding machines have become essential tools for innovation. They bridge the gap between standardization and customization, enabling manufacturers to produce high-quality components tailored to the most demanding applications.

From large transformer coils to compact drive-by-wire actuators, the future of coil technology lies in automation, precision, and intelligent customization — all driven by advanced machinery and visionary manufacturers who understand that every coil counts.

www.jsxlmachines.com

Jiangsu Xianglong Electromechanical Co., Ltd.