Top Benefits of Implementing Active Vibration Damping in Automotive and Aerospace Systems

admin 2026-02-11 0

In today’s high-performance automotive and aerospace industries, vibration control is no longer just a luxury—it is a necessity. Excessive vibrations can compromise vehicle stability, reduce passenger comfort, shorten equipment lifespan, and affect the precision of sensitive aerospace components. Active vibration damping (AVD) has emerged as a cutting-edge solution that actively mitigates unwanted vibrations in real time, outperforming traditional passive systems.

This article explores the top benefits of implementing active vibration damping in automotive and aerospace applications, highlighting innovations from Wuhan Glory Road Precision Technology Co., Ltd., a leading manufacturer of advanced active vibration isolation equipment.

What Is Active Vibration Damping?

Active vibration damping is a technology that uses sensors, actuators, and advanced control algorithms to detect and counteract vibrations as they occur. Unlike passive damping systems that rely on springs, dampers, or materials to absorb energy, AVD systems actively apply opposing forces to cancel vibrations, ensuring enhanced stability, safety, and precision.

Wuhan Glory Road Precision Technology Co., Ltd. specializes in active vibration isolation platforms, motion controllers, and fully integrated mechatronic systems that provide decisive competitive advantages across automotive, aerospace, and precision engineering applications.

Top Benefits of Active Vibration Damping in Automotive Systems

1. Enhanced Ride Comfort and Passenger Safety

Active vibration damping reduces vibrations transmitted from the road to the vehicle chassis, suspension, and cabin. This leads to smoother rides, less fatigue for drivers and passengers, and improved vehicle handling during high-speed or uneven terrain driving.

2. Improved Vehicle Stability and Control

By minimizing body roll, suspension oscillations, and chassis vibrations, AVD systems enhance steering precision and overall vehicle stability, particularly in sports cars, electric vehicles, and heavy-duty trucks.

3. Extended Component Lifespan

Excessive vibrations accelerate wear on critical components such as engines, transmissions, and suspension systems. Active vibration damping reduces mechanical stress, extending the service life of these components and lowering maintenance costs.

4. Noise Reduction

AVD systems also contribute to lower noise levels inside the vehicle cabin by reducing vibration-induced resonances, creating a quieter and more refined driving experience.

Top Benefits of Active Vibration Damping in Aerospace Systems

1. Precision and Accuracy in Aircraft and Spacecraft

High-frequency vibrations can compromise the accuracy of avionics, sensors, and satellite equipment. Active vibration damping ensures critical systems operate within strict tolerances, improving mission success rates and operational reliability.

2. Structural Safety and Longevity

By dynamically countering vibrations from engines, aerodynamic forces, and environmental turbulence, AVD systems help protect aircraft fuselages, wings, and sensitive equipment from fatigue and structural damage.

3. Enhanced Passenger Comfort

In commercial aviation, AVD technology reduces cabin vibrations, improving comfort for passengers and crew during takeoff, flight turbulence, and landing.

4. Support for Advanced Aerospace Applications

Active vibration damping is essential in aerospace testing, satellite assembly, and spacecraft launch preparation, where precise vibration control is critical to success.

Why Partner with Wuhan Glory Road Precision Technology Co., Ltd.

Wuhan Glory Road Precision Technology Co., Ltd. delivers state-of-the-art active vibration damping solutions designed to meet the demands of automotive and aerospace industries. Their offerings include:

-

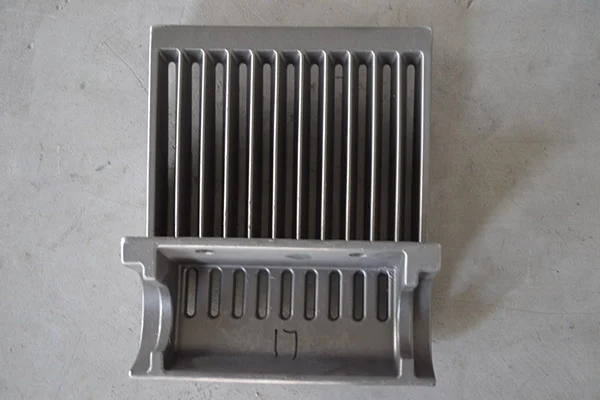

Advanced active vibration isolation platforms for vehicles and machinery

-

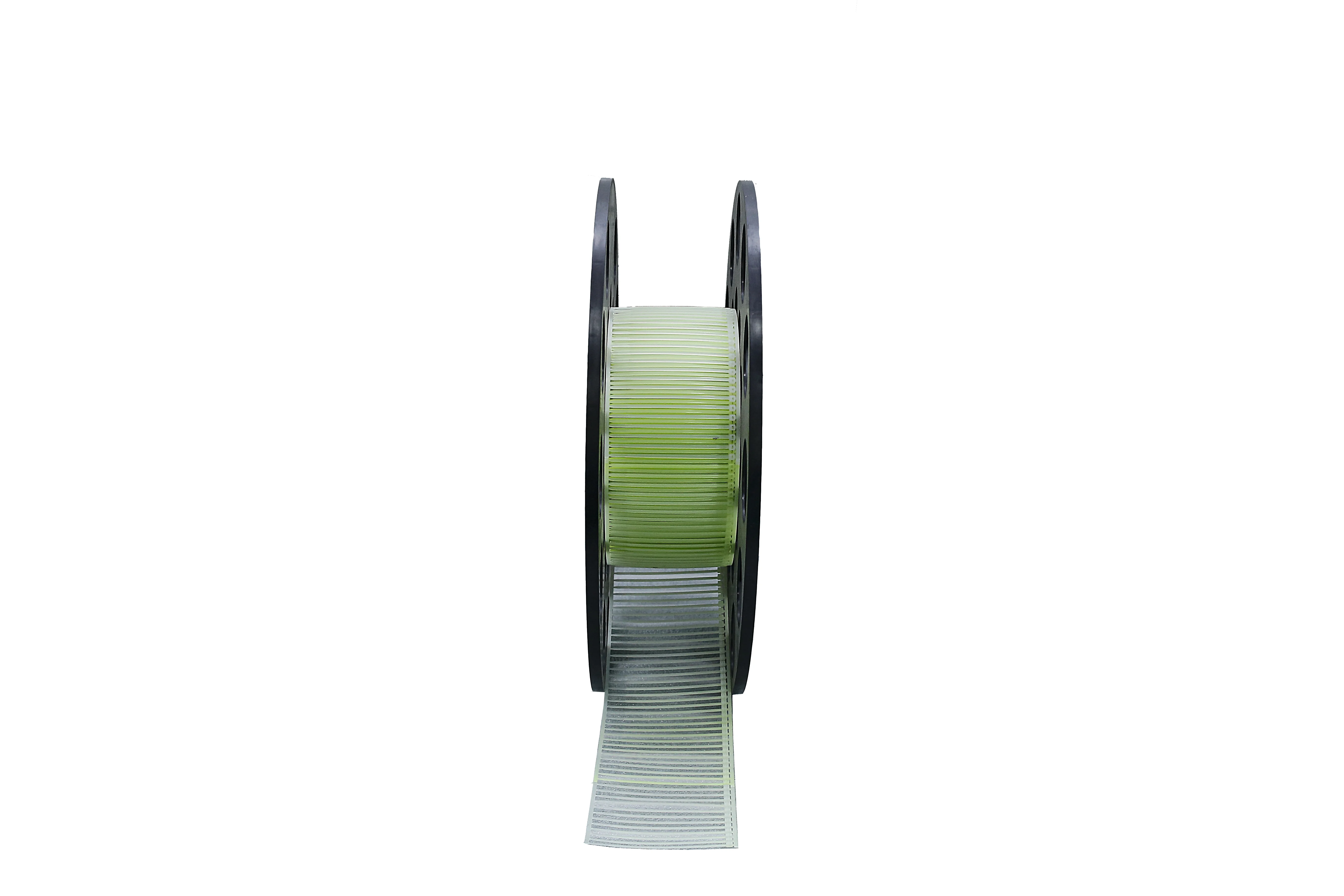

High-performance motion controllers for real-time vibration suppression

-

Fully integrated mechatronic systems tailored to customer applications

By combining cutting-edge technology with engineering expertise, Wuhan Glory Road ensures that clients gain decisive competitive advantages, including improved product performance, extended lifespan, and enhanced safety.

Conclusion

Implementing active vibration damping in automotive and aerospace systems provides a multitude of benefits, from improved ride comfort and vehicle stability to precision control and structural safety in aerospace applications.

With trusted partners like Wuhan Glory Road Precision Technology Co., Ltd., industries can leverage advanced active vibration isolation platforms, motion controllers, and integrated mechatronic systems to stay ahead in competitive markets, reduce maintenance costs, and deliver superior performance and safety for both vehicles and aircraft.

Active vibration damping is not just a technological upgrade—it is a strategic investment in performance, reliability, and competitive advantage.

www.glroadprecision.com

Wuhan Glory Road Precision Technology Co., Ltd.