Top Benefits of Using the Best Industrial Contact Plate Freezer for Fast and Uniform Freezing

In modern food processing, freezing speed and product consistency directly affect quality, yield, and operational efficiency. As consumer demand for high-quality frozen foods continues to grow, manufacturers are under increasing pressure to adopt freezing solutions that are fast, reliable, and energy-efficient. Among the available technologies, the industrial contact plate freezer stands out as one of the most effective systems for fast and uniform freezing.

This article explores the key benefits of using the best industrial contact plate freezer and explains why it has become a preferred choice for many food processing applications.

Fast Freezing That Preserves Product Quality

One of the biggest advantages of an industrial contact plate freezer is its ability to freeze products rapidly through direct contact between the plates and the food surface. This efficient heat transfer significantly reduces freezing time compared to air-based freezing methods.

Faster freezing helps form smaller ice crystals within the product, which means:

-

Better preservation of texture and structure

-

Reduced drip loss after thawing

-

Improved appearance and mouthfeel

For products such as fish fillets, meat blocks, ready meals, and processed foods, fast freezing is essential to maintaining original quality.

Uniform Freezing for Consistent Results

Uniform freezing is critical in large-scale food production. Uneven freezing can lead to quality variations, food safety risks, and difficulties in downstream processing.

Industrial contact plate freezers apply consistent pressure and temperature across the product surface, ensuring even heat removal. This results in:

-

Consistent core temperatures

-

Predictable freezing cycles

-

Stable product dimensions and weight

Uniform freezing is especially important for block-shaped or packaged products where consistency is required for storage, slicing, or further processing.

High Energy Efficiency and Lower Operating Costs

Compared with traditional blast freezers, contact plate freezers are known for their high energy efficiency. Direct heat exchange minimizes energy loss and shortens operating cycles, leading to lower power consumption.

Key efficiency benefits include:

-

Reduced refrigeration load

-

Lower energy costs per kilogram of product

-

Optimized use of floor space

These advantages make contact plate freezers particularly attractive for processors seeking long-term cost savings without compromising performance.

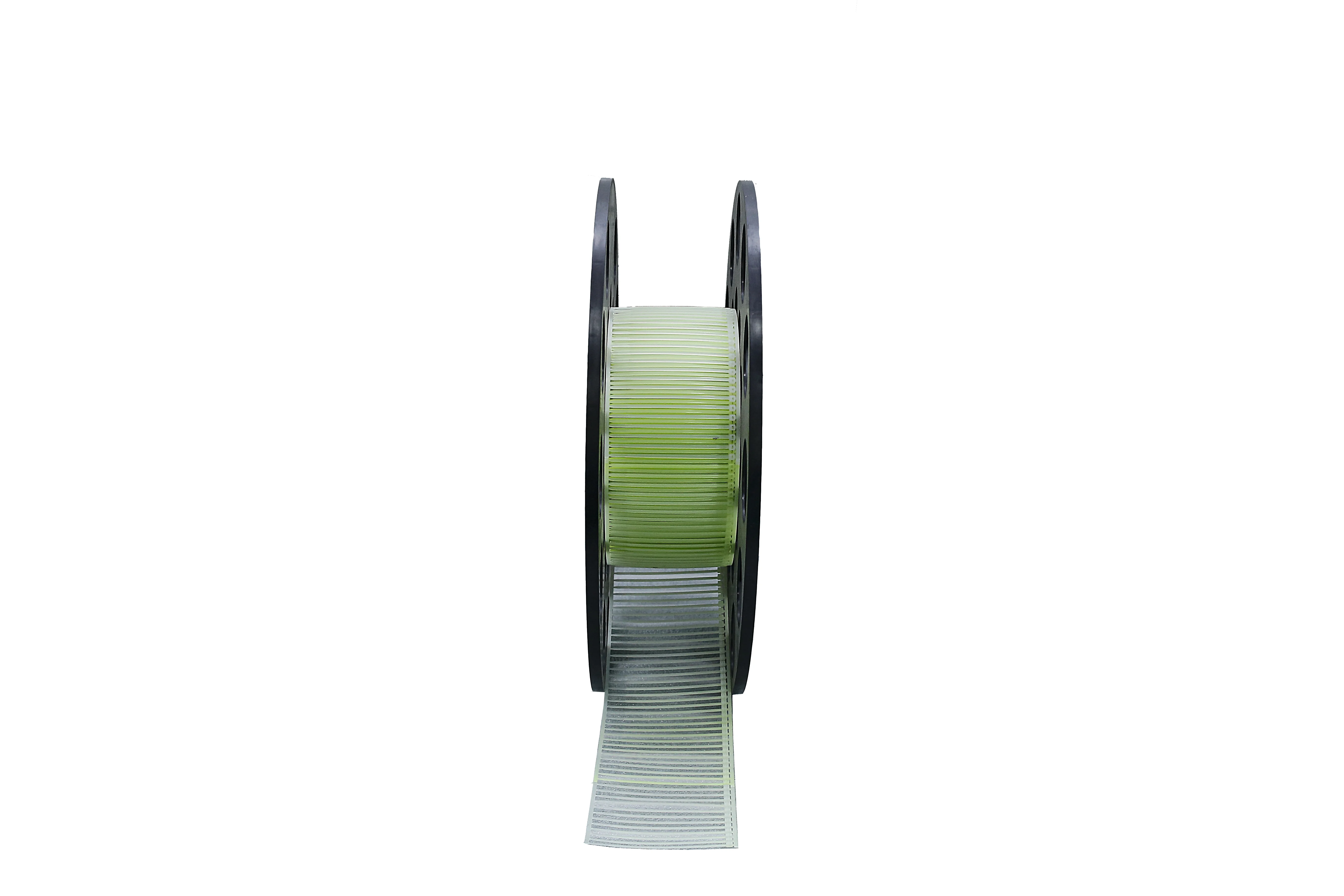

Compact Design and Space Optimization

Industrial contact plate freezers are typically designed with a compact footprint, making them suitable for facilities with limited space. Their vertical or horizontal configurations allow flexible integration into existing production lines.

By optimizing space utilization, food processors can:

-

Increase production capacity within the same facility

-

Improve workflow efficiency

-

Simplify installation and maintenance

This flexibility is valuable for both new plant construction and equipment upgrades.

Reliable Performance for High-Volume Processing

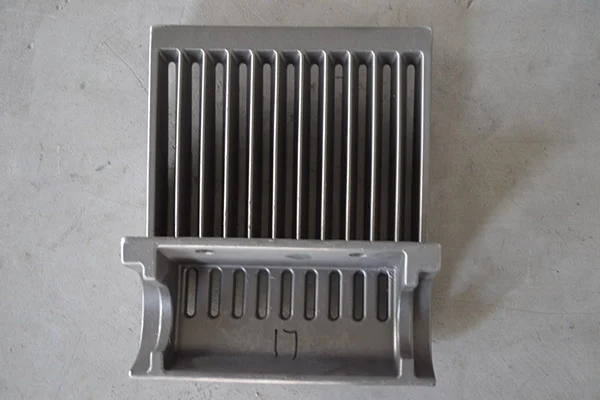

For high-throughput operations, equipment reliability is critical. The best industrial contact plate freezers are built to handle continuous operation under demanding conditions while maintaining stable freezing performance.

High-quality systems are designed with:

-

Durable structural components

-

Precise temperature control

-

Easy cleaning and maintenance features

This reliability reduces downtime and supports consistent production schedules.

Integrated Freezing Solutions for Modern Food Processing

Selecting the right freezer is only one part of building an efficient freezing operation. Process design, system integration, and after-sales support are equally important.

Nantong Sinrofreeze Equipment Co., Ltd. is a high-tech enterprise specializing in complete food freezing system solutions. The company integrates research and development, design, manufacturing, sales, and service to support food processors throughout the entire project lifecycle.

By providing food processing flow design and freezing systems that focus on safety, efficiency, and low energy consumption, Sinrofreeze helps customers optimize freezing performance while controlling operating costs.

Applications Across the Food Industry

Industrial contact plate freezers are widely used in various food sectors, including:

-

Seafood processing

-

Meat and poultry production

-

Prepared meals and ready-to-eat foods

-

Dairy and plant-based products

Their versatility and performance make them a reliable solution for manufacturers aiming to meet strict quality and safety standards.

Conclusion

Using the best industrial contact plate freezer offers clear advantages in terms of freezing speed, uniformity, energy efficiency, and operational reliability. For food processors focused on quality preservation and cost control, this technology provides a proven and scalable solution.

With its expertise in complete food freezing systems and commitment to safe, efficient, and low-energy solutions, Nantong Sinrofreeze Equipment Co., Ltd. supports food manufacturers in achieving higher freezing efficiency and long-term production stability in an increasingly competitive market.

www.sinrofreezer.com

Nantong Sinrofreeze Equipment Co., Ltd.