Can Mechanical Seals Be Repaired? Exploring the Viability and Benefits

Mechanical seals are critical components used in various industries to prevent leakage in rotating equipment such as pumps and compressors. Over time, these seals may experience wear and tear, leading to potential leaks. This article aims to delve into the question of whether mechanical seals can be repaired, exploring the viability and benefits of repair options.

- Understanding Mechanical Seals:

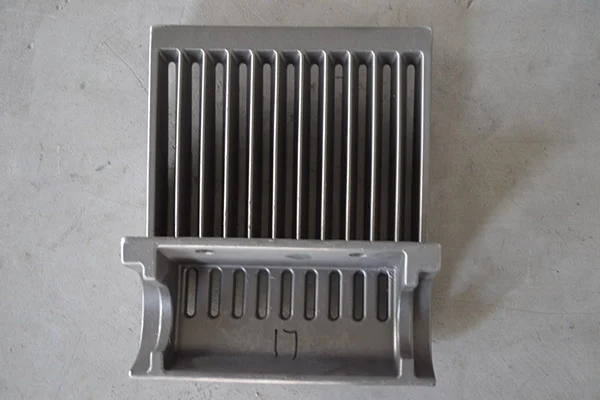

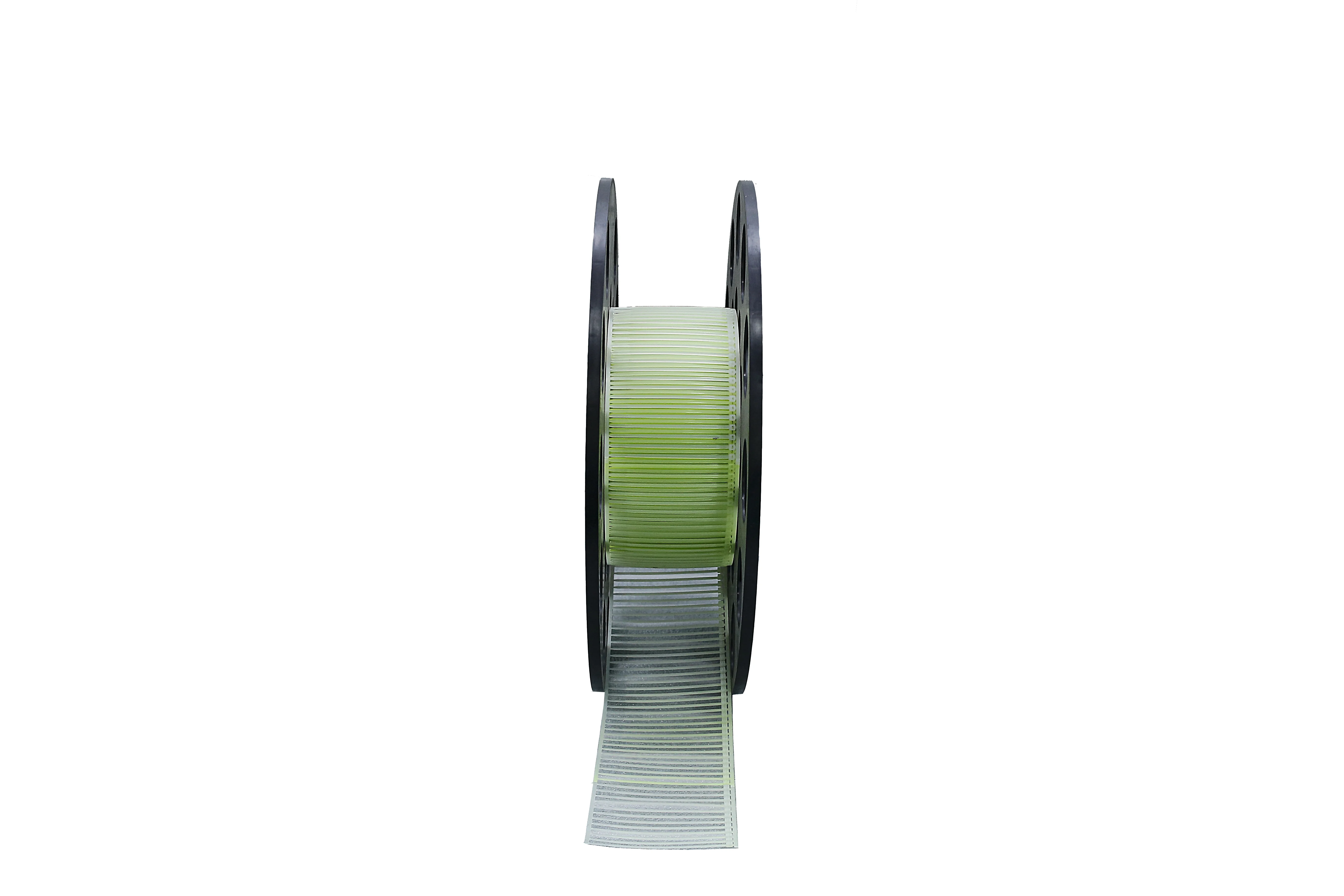

Before discussing repair options, it is essential to understand the basic structure and function of mechanical seals. Mechanical seals consist of two main components: a stationary part attached to the pump housing and a rotating part connected to the pump shaft. These components work together to create a barrier, preventing fluid leakage. - Common Causes of Mechanical Seal Damage:

To determine whether repair is possible, it is crucial to identify the common causes of mechanical seal damage. These include abrasive particles in the fluid, improper installation, excessive heat, pressure fluctuations, and shaft misalignment. Understanding the root cause of the damage can help in assessing the repair feasibility. - Evaluation of Repair Options:

a. Seal Refurbishment: In some cases, mechanical seals can be refurbished by replacing worn-out components such as O-rings, springs, and sealing faces. This option is cost-effective and can extend the seal's lifespan. However, it is essential to consider the seal's condition and the availability of spare parts.

b. Seal Reconditioning: For more severe damage, reconditioning the mechanical seal may be necessary. This involves repairing or replacing damaged components and restoring the seal to its original specifications. Reconditioning can be a viable option for high-quality seals with complex designs.

c. Seal Replacement: In cases where the damage is extensive or the seal is beyond repair, replacement becomes the only option. It is crucial to consult with experts to determine the most suitable replacement seal based on the equipment's specifications and operating conditions.

- Benefits of Repairing Mechanical Seals:

a. Cost Savings: Repairing mechanical seals can be significantly more cost-effective than replacing them entirely. By refurbishing or reconditioning seals, businesses can save on purchasing new seals and reduce downtime associated with equipment replacement.

b. Environmental Impact: Repairing mechanical seals aligns with sustainable practices by reducing waste generation. Extending the lifespan of seals through repair contributes to a greener approach in industrial operations.

c. Enhanced Equipment Performance: Well-maintained and repaired mechanical seals can improve equipment performance by minimizing leakage and ensuring optimal sealing efficiency. This, in turn, leads to increased productivity and reduced maintenance costs.

Conclusion:

In conclusion, mechanical seals can be repaired depending on the extent of damage and the availability of suitable repair options. Refurbishment and reconditioning are viable alternatives to replacement, offering cost savings, environmental benefits, and improved equipment performance. However, it is crucial to assess each situation individually and consult with experts to determine the most appropriate course of action. By prioritizing seal repair, industries can optimize their operations while minimizing costs and environmental impact.