The Silent Culprit: Unveiling the Secrets of Transformer Damage

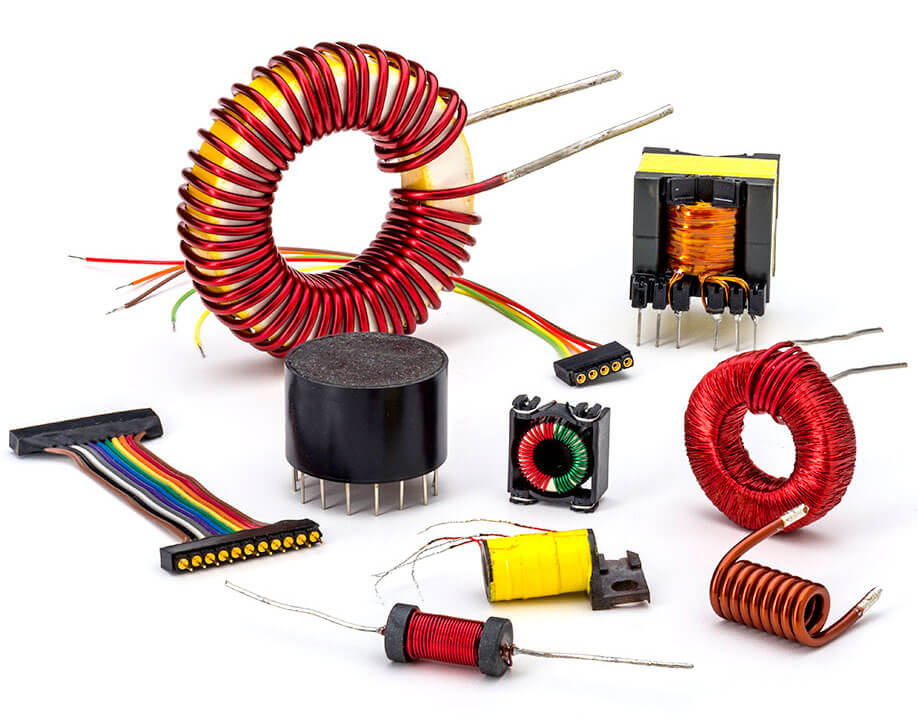

Transformers are vital components in electrical systems, responsible for transferring electrical energy between circuits. However, these complex devices are not immune to damage. Understanding how a transformer can get damaged is crucial for ensuring the reliability and longevity of electrical systems. In this article, we will delve into the various factors that can lead to transformer damage and explore practical solutions to mitigate these risks.

- Overloading:

One of the primary causes of transformer damage is overloading. When a transformer is subjected to excessive electrical load beyond its rated capacity, it can overheat, leading to insulation breakdown and potential failure. Factors such as increased power demand, faulty equipment, or improper load management can contribute to overloading. Implementing load monitoring systems and conducting regular load assessments can help prevent this type of damage. - Voltage Surges:

Voltage surges, also known as transients, can occur due to lightning strikes, switching operations, or faults in the power grid. These sudden spikes in voltage can cause insulation breakdown, leading to transformer damage. Installing surge protection devices, such as surge arresters, can help divert excessive voltage and protect transformers from damage. - Insulation Deterioration:

Over time, the insulation materials used in transformers can deteriorate due to factors like heat, moisture, and chemical exposure. This degradation weakens the insulation's ability to withstand electrical stress, increasing the risk of transformer failure. Regular maintenance, including insulation testing and moisture control, is essential to detect and address insulation deterioration promptly. - Contamination:

Contaminants, such as dust, moisture, and conductive particles, can accumulate on transformer surfaces and inside the windings. This contamination can lead to reduced insulation resistance, increased heat generation, and eventual transformer damage. Implementing proper sealing, regular cleaning, and periodic oil analysis can help mitigate the effects of contamination and extend transformer lifespan. - Mechanical Stress:

Transformers are subjected to various mechanical stresses, including vibrations, thermal expansion, and short circuits. These stresses can cause structural damage, loosening of connections, and insulation displacement, leading to performance degradation or even catastrophic failure. Adequate design considerations, such as vibration dampening, thermal protection, and robust construction, are crucial to minimize mechanical stress-related damage.

Conclusion:

Transformers play a vital role in electrical systems, and understanding the factors that can lead to their damage is essential for ensuring reliable and efficient operation. By addressing issues such as overloading, voltage surges, insulation deterioration, contamination, and mechanical stress, we can significantly reduce the risk of transformer failure. Implementing preventive measures, conducting regular maintenance, and staying updated with industry best practices are key to safeguarding transformers and optimizing the performance of electrical systems.