Common Issues with Chain Grating Machine Grate Side Plates and How to Solve Them

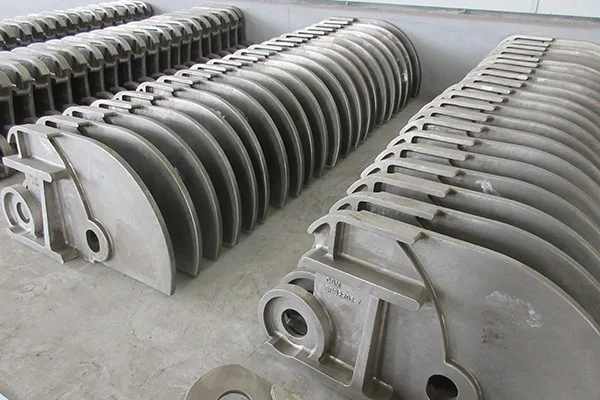

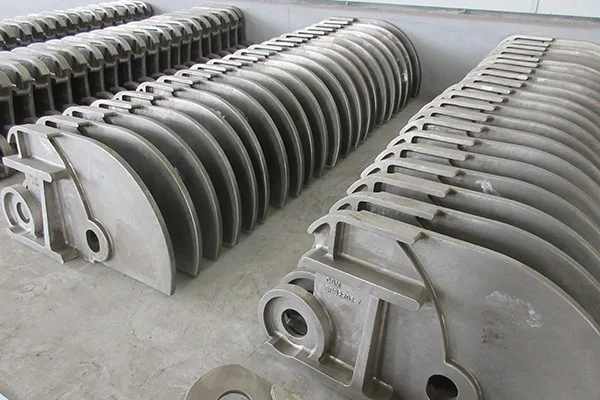

Chain grating machines are essential in heavy-duty industrial applications, including metallurgy, cement, ceramics, forging, shipbuilding, and chemical processing. A key component of these machines is the grate side plate, which supports and guides the grating chain. While durable, these components can experience issues that affect machine performance, efficiency, and safety.

China Special Metal Group Limited (CSM) is a trusted supplier of high-quality cast steel components, precision-machined products, and welded items for industrial machinery. Serving multiple industries worldwide, CSM ensures clients receive durable and reliable parts, including customized grate side plates for chain grating machines.

Common Issues with Grate Side Plates

1. Wear and Abrasion

Chain grating machines handle heavy loads, abrasive materials, and high friction environments. Over time, the side plates can experience surface wear or thinning, which may lead to chain misalignment and reduced machine efficiency.

Solution:

Use high-quality cast steel or alloy side plates with wear-resistant coatings. Regularly inspect and replace plates showing excessive wear to prevent damage to other machine components.

2. Misalignment

Improper installation or deformation of side plates can cause the grating chain to deviate from its track, leading to jerky movement, uneven loading, or even chain breakage.

Solution:

Ensure precise installation following manufacturer guidelines. Choose precision-engineered grate side plates from suppliers like CSM, which are custom-made for specific chain grating machine models.

3. Corrosion and Rust

Exposure to moisture, chemicals, or high humidity can cause corrosion on side plates, weakening their structural integrity over time.

Solution:

Select corrosion-resistant materials or coated steel plates. Implement regular cleaning and maintenance routines to minimize exposure to corrosive elements.

4. Cracks and Structural Damage

Heavy operational loads, thermal stress, or manufacturing defects can result in cracks or fractures in the side plates. This poses safety risks and may halt production.

Solution:

Regularly inspect plates for cracks using visual and ultrasonic testing. Opt for high-quality cast steel plates with superior mechanical properties to withstand operational stress.

5. Improper Sizing or Fit

Using generic or poorly fitting plates can cause misalignment, uneven wear, or machine downtime.

Solution:

Work with reputable suppliers like CSM to obtain customized grate side plates that match your specific machine dimensions and operational requirements.

Best Practices to Extend the Lifespan of Grate Side Plates

-

Routine Inspection: Check for wear, corrosion, cracks, and alignment issues on a regular schedule.

-

Lubrication: Ensure the grating chain and side plates are properly lubricated to reduce friction.

-

Load Management: Avoid overloading the machine, which can accelerate plate wear.

-

Timely Replacement: Replace worn or damaged plates immediately to prevent further machine damage.

-

Professional Installation: Ensure plates are installed by trained technicians according to manufacturer specifications.

Why Choose CSM for Grate Side Plates

China Special Metal Group Limited (CSM) provides high-quality cast steel and precision-engineered components tailored for demanding industrial environments. Their products are designed to withstand heavy loads, abrasion, and chemical exposure, making them ideal for chain grating machines across multiple industries:

-

Metallurgy – Handling slag and ore efficiently

-

Cement & Building Materials – Transporting clinker and aggregates

-

Ceramics & Forging – Managing heavy materials during production

-

Shipbuilding & Chemical Processing – Ensuring safe and reliable material handling

With CSM, clients benefit from durable, reliable, and custom-fit grate side plates that minimize downtime and maintenance costs.

Conclusion

Chain grating machine grate side plates are critical for smooth operation and long-term reliability. Understanding common issues such as wear, misalignment, corrosion, cracks, and improper fit allows operators to implement proactive solutions. By choosing high-quality, precision-engineered plates from trusted suppliers like China Special Metal Group Limited (CSM), industries can improve machine efficiency, enhance safety, and reduce operational costs.

www.special-metal.com

China Special Metal Group Limited (CSM)