Enhancing Safety and Reliability with the Sunlightweld Smart Grounding Monitoring System

In electrical and industrial environments, grounding is the fundamental backbone of equipment safety. A stable grounding system not only ensures fault current dispersion and protects equipment, but it also safeguards personnel and critical assets from dangerous electrical surges and lightning strikes. However, traditional grounding inspection methods often rely on manual measurement, periodic testing, and on-site observation. These approaches are time-consuming, labor-intensive, and often fail to detect early-stage grounding deterioration. In contrast, real-time monitoring enables immediate awareness of potential risks and supports proactive maintenance strategies. This is where the smart grounding monitoring system becomes essential.

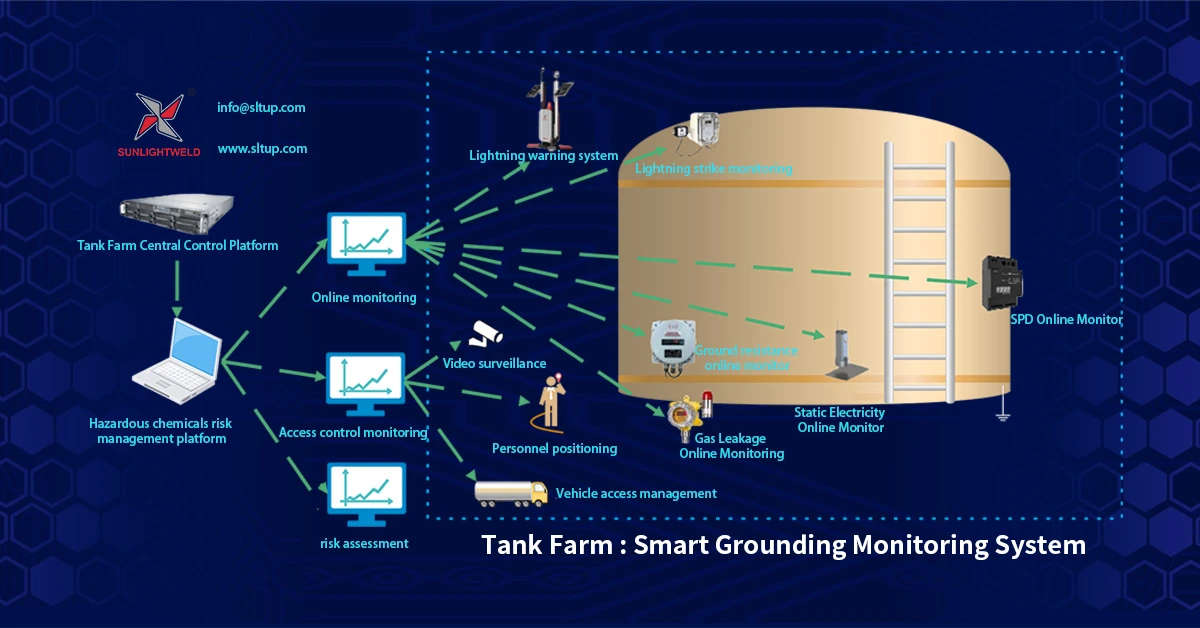

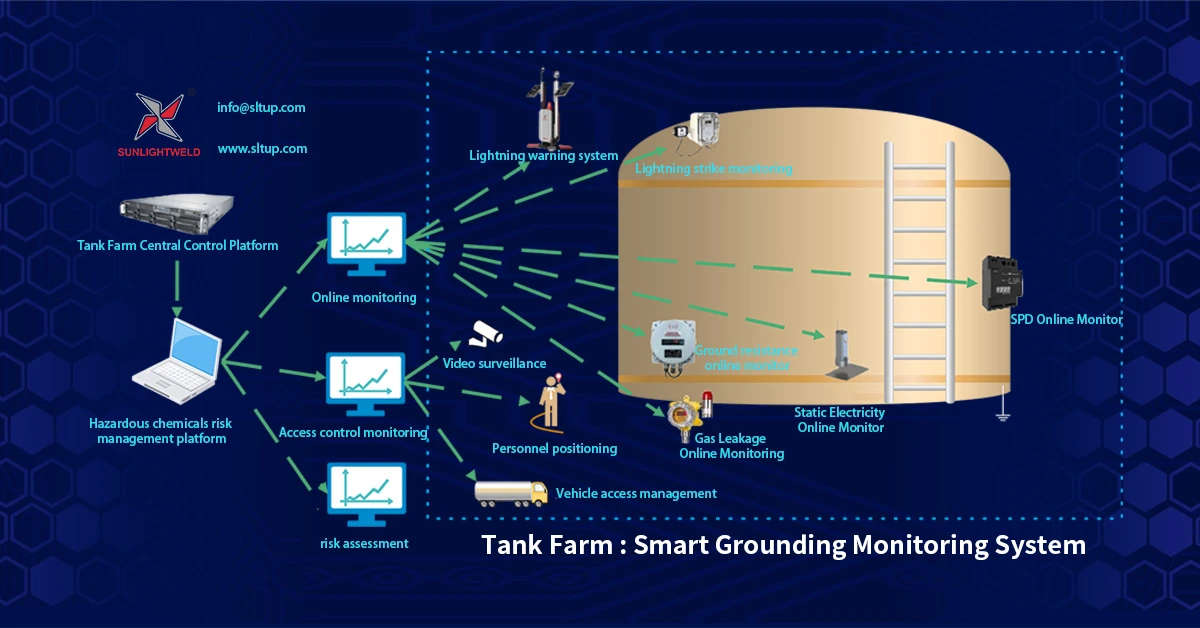

The Sunlightweld smart grounding monitoring system is a next-generation intelligent solution that combines real-time data acquisition, remote supervision, predictive maintenance analysis, and visual interface management. Designed to elevate grounding safety management practices, this system helps industrial sites avoid grounding failures, improve operational efficiency, and reduce maintenance costs.

What is the Smart Grounding Monitoring System?

A smart grounding monitoring system is an intelligent solution used to continuously monitor the health and performance of grounding networks. Unlike traditional manual inspections, which only provide periodic data, a smart grounding monitoring system works 24/7, automatically tracking grounding resistance and environmental conditions in real time. When abnormal values or sudden changes occur, the system instantly sends alerts so that maintenance personnel can respond quickly.

The Sunlightweld smart grounding monitoring system integrates data collection, alarm notifications, remote viewing, and historical trend analysis into one platform. This allows users to detect potential grounding issues early, prevent equipment failures, and improve overall operational safety.

Functions of Sunlightweld Smart Grounding Monitoring System

Real-Time Grounding Performance Monitoring

The Sunlightweld smart grounding monitoring system continuously monitors key grounding indicators such as grounding resistance, atmospheric electric field intensity, and five major meteorological elements. This comprehensive detection approach enables accurate tracking of grounding performance in real time. Once abnormal fluctuations or faults are detected, the system immediately issues alerts via email and SMS to designated personnel. This minimizes response time and prevents small issues from escalating into serious safety threats.

Through the system's continuous monitoring capabilities, users can gain clear insight into grounding conditions, environmental changes, and potential hazard factors. This reduces the uncertainty associated with grounding checks and improves overall grounding reliability.

Fault Localization and Rapid Response

One of the core strengths of the Sunlightweld smart grounding monitoring system is its ability to support fault localization. When grounding resistance exceeds set thresholds or grounding conditions degrade, the system will send instant alarms to maintenance personnel. This ensures that personnel can quickly identify the affected equipment or grounding node and take corrective action. Fast fault handling is crucial for facilities such as substations, petrochemical plants, communication towers, and rail systems, where grounding failures can lead to operational interruptions and severe safety incidents.

By improving fault response speed, the system enhances equipment uptime and operational continuity.

Remote Monitoring and Centralized Management

The Sunlightweld smart grounding monitoring system offers remote access capabilities, enabling users to view system status at any time, whether on-site or off-site. Maintenance personnel and decision-makers can log into the platform through computers, tablets, or smartphones to check each grounding point’s performance indicators and operational status.

Remote monitoring reduces the need for frequent field inspections, saving labor and travel costs. It also allows supervisory teams to make timely strategic decisions and schedule maintenance tasks more efficiently. This level of control greatly enhances management convenience for large-scale distributed facilities.

Predictive Maintenance Through Trend Analysis

A major advantage of adopting a smart grounding monitoring system is the ability to apply predictive maintenance strategies. The Sunlightweld smart grounding monitoring system continuously records and stores collected data, including historical resistance values and alarm records. By analyzing long-term data trends, the system can identify early signs of grounding deterioration.

This allows users to schedule preventative maintenance operations before a failure occurs, reducing unexpected downtime and avoiding costly damage. Predictive maintenance also optimizes maintenance planning and budget allocation, bringing notable operational efficiency benefits.

User-Friendly & Visualized Interface

The system features an intuitive visualization interface displaying real-time monitoring data, alarm statistics, device status summaries, and historical performance graphs. This makes it easy for users to quickly understand grounding network conditions without requiring specialized technical knowledge.

The user-friendly interface design ensures smooth navigation, simple operation workflows, and fast learning—even for personnel with minimal training. With only minimal setup, the system can be seamlessly integrated into existing safety management workflows.

Non-Contact Measurement Technology with No System Modifications Needed

The Sunlightweld smart grounding monitoring system is designed to be compatible with existing grounding system architectures. It does not require modifications to the original grounding design and uses non-contact measurement technologies to perform online monitoring without interfering with grounding continuity or equipment operation.

The system does not require periodic self-testing and supports real-time continuous monitoring. It can be deployed as a standalone configuration or integrated into wired or wireless network systems. Data storage capabilities enable long-term trend curves that clearly illustrate grounding network conditions and help assess grounding health status.

Sunlightweld: Trusted Partner in Grounding & Lightning Protection Solutions

Sunlightweld is a global earthing materials, grounding products, earthing system, and lightning protection supplier, manufacturer, and factory. Backed by advanced engineering capabilities and a strong China-origin supply chain, Sunlightweld provides cost-effective solutions that help customers achieve at least 30% higher profit margins compared to sourcing from other international brands.The company is actively expanding its global partnership network and welcomes collaboration with distributors, EPC contractors, project integrators, and engineering firms.

The Sunlightweld smart grounding monitoring system offers a powerful solution to modern industrial grounding challenges. With real-time monitoring, fault localization, remote supervision, predictive maintenance, intuitive data visualization, and extreme environmental durability, it ensures stable system grounding while reducing operational risks and maintenance costs.

As industries increasingly prioritize reliability and safety, traditional grounding inspection is no longer sufficient. The Sunlightweld smart grounding monitoring system represents the future of grounding management—intelligent, automated, and data-driven.

https://www.sltup.com/Earth-Resistance-Online-Detector-Factory-Price-China-Manufacturer.html

www.sltup.com

Sunlightweld