How a Wood Pellet Mill Works: From Raw Materials to Finished Pellets

The global demand for biomass energy has made wood pellets one of the most widely used renewable fuels for heating and power generation. At the heart of this industry is the wood pellet mill, a system designed to convert raw biomass into uniform, high-density fuel pellets. Understanding how a wood pellet mill works is essential for manufacturers, investors, and plant operators who want consistent output, stable quality, and long-term operational efficiency.

1. Raw Material Selection and Preparation

The pelletizing process begins with raw materials. Common feedstocks include wood chips, sawdust, wood shavings, forestry residues, and agricultural by-products such as straw or rice husk. For wood pellet mills, sawdust and wood chips are the most commonly used due to their stable fiber structure and high calorific value.

Raw material quality directly affects pellet density, durability, and energy efficiency. Before entering the pellet mill system, materials must meet two key conditions:

-

Moisture content: Typically controlled between 10% and 15%

-

Particle size: Uniform and fine enough for compression

Oversized or wet materials reduce pellet quality and increase energy consumption during processing.

2. Crushing and Size Reduction

If raw materials are in the form of wood chips or branches, they must be reduced to suitable particle size. This is done using a hammer mill or wood crusher. The goal is to produce consistent particles, usually smaller than 5 mm.

Uniform particle size ensures:

-

Even compression inside the pellet mill

-

Stable pellet density

-

Reduced wear on the die and rollers

In practical production lines, crushing efficiency directly affects pellet mill throughput and power consumption.

3. Drying Process

Moisture control is one of the most critical steps in pellet production. Excess moisture prevents proper pellet formation, while overly dry material reduces binding strength.

Rotary drum dryers or belt dryers are commonly used to reduce moisture to the optimal range. The drying system is often integrated into a complete wood pellet production line, allowing continuous processing without material backlog.

Modern pellet plants focus on energy-efficient drying methods, often reusing waste heat from other processes to lower operating costs.

4. Conditioning Before Pelletizing

Before entering the pellet mill, raw materials may pass through a conditioner. This step stabilizes temperature and moisture content and improves material flow.

In wood pellet mills, natural lignin within the wood fibers acts as a binding agent when heated under pressure. Proper conditioning ensures lignin activation, which improves pellet hardness and durability without chemical additives.

5. Pelletizing: The Core of the Process

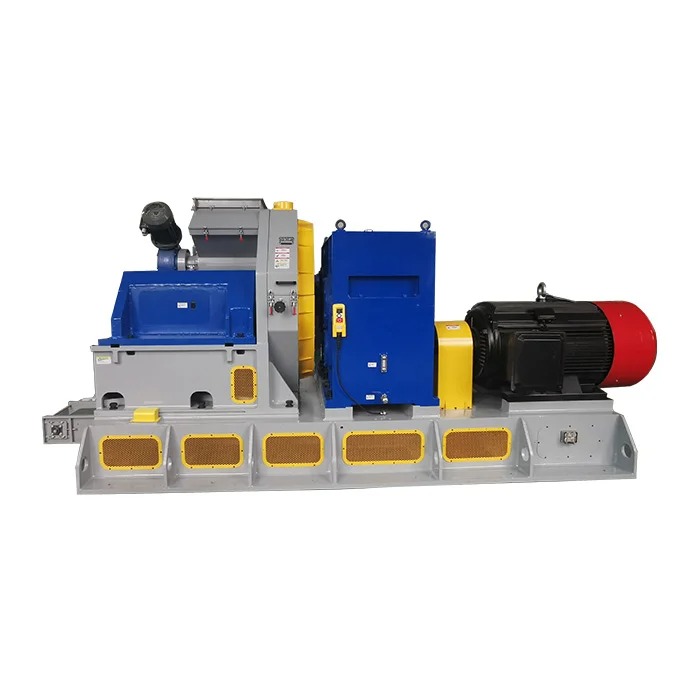

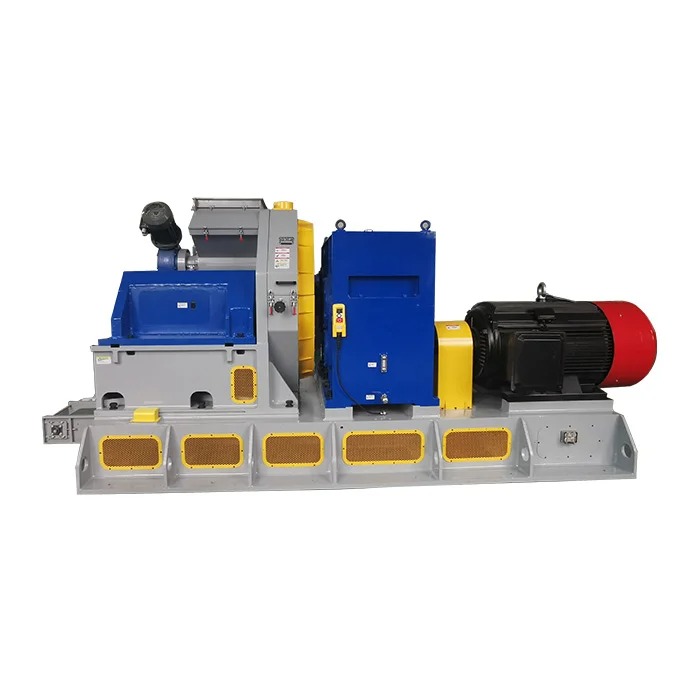

The pellet mill itself is the core equipment in the system. Inside the mill, material is forced through a steel die by rotating rollers. Under high pressure and temperature, biomass fibers are compressed into cylindrical pellets.

There are two common pellet mill designs:

-

Ring die pellet mills

-

Flat die pellet mills

For industrial-scale production, ring die pellet mills are preferred due to higher capacity, longer service life, and better stability.

Manufacturers such as Beisier focus on pellet mill designs that balance pressure, roller-die clearance, and material flow to ensure consistent pellet output. Many modern systems integrate automation and monitoring features to optimize performance and reduce downtime.

For users seeking complete pellet mill solutions and supporting equipment, professional production systems can be explored through specialized product platforms such as wood pellet mill equipment solutions, which cover multiple processing stages.

6. Cooling and Hardening of Pellets

Freshly formed pellets exit the pellet mill at high temperature and are relatively soft. Cooling is essential to harden the pellets and stabilize their structure.

Counterflow coolers are commonly used to:

-

Reduce pellet temperature

-

Lower residual moisture

-

Increase mechanical strength

Proper cooling minimizes pellet breakage during storage and transport, which is critical for commercial distribution.

7. Screening and Recycling Fines

After cooling, pellets pass through a vibrating screen to separate fines and broken pieces. These fines are not waste; they are typically returned to the pellet mill for reprocessing.

This closed-loop system:

-

Improves raw material utilization

-

Reduces production waste

-

Maintains consistent pellet quality

Efficient screening systems are a sign of a well-designed pellet production line.

8. Packaging and Storage

The final step is packaging or bulk storage. Depending on the target market, pellets may be:

-

Packed in small bags for residential heating

-

Stored in bulk for industrial or power plant use

Proper packaging protects pellets from moisture absorption and mechanical damage. Storage facilities must be dry, ventilated, and designed to prevent pellet degradation.

9. Why Process Integration Matters

A wood pellet mill does not operate in isolation. Its performance depends on how well it integrates with upstream and downstream equipment. Poor coordination between drying, pelletizing, and cooling stages leads to energy waste, unstable output, and increased maintenance costs.

This is why experienced manufacturers like Beisier emphasize complete system design rather than single-machine sales. A well-integrated pellet line improves efficiency, reduces operational risks, and ensures long-term production stability.

Conclusion

A wood pellet mill works through a carefully coordinated process that transforms raw biomass into dense, energy-efficient fuel pellets. Each stage—crushing, drying, conditioning, pelletizing, cooling, and packaging—plays a critical role in final product quality.

For companies entering or expanding in the biomass energy sector, understanding this process is essential. Choosing the right equipment, optimizing system integration, and working with experienced pellet mill manufacturers are key steps toward building a reliable and profitable pellet production operation.

www.bsr-wood.com

Beisier