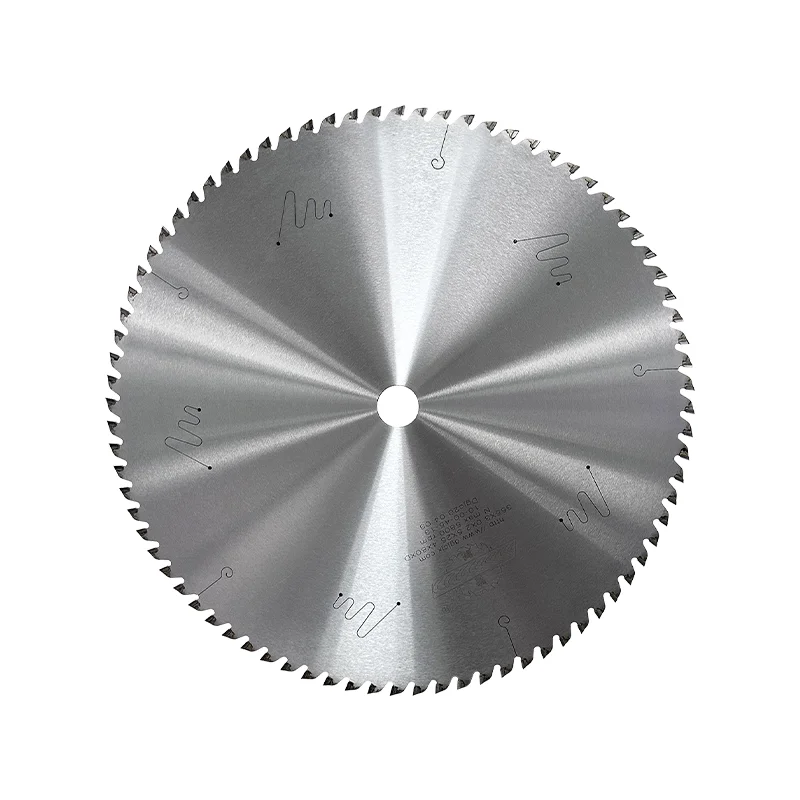

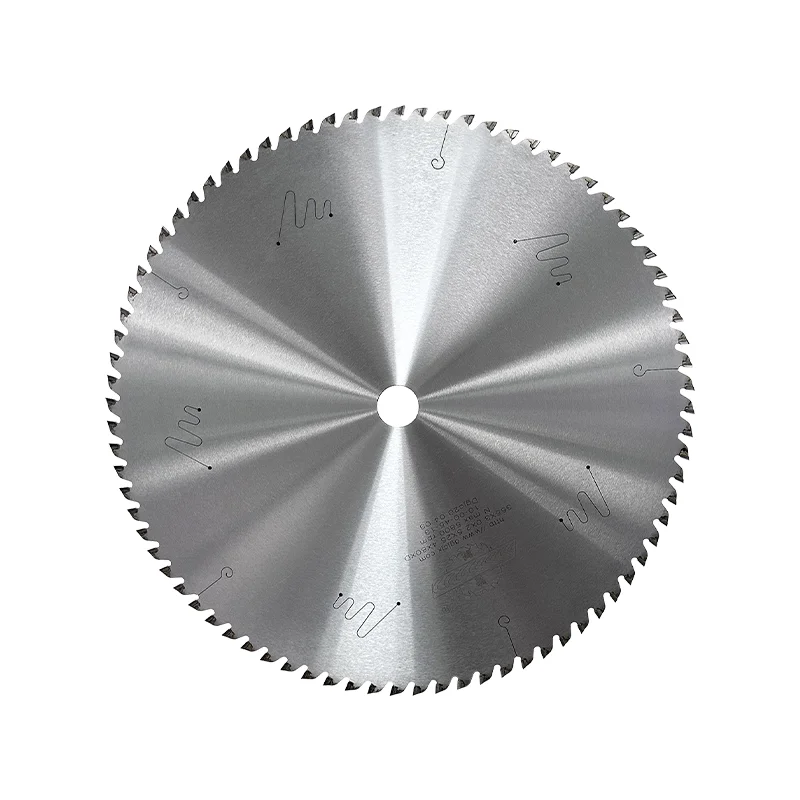

How to extend the life of your circular saw blades?

Circular saw blades are one of the most important consumables in the cutting and processing of materials such as wood, metal, and plastic. Due to their high strength and high precision, circular saw blades play a vital role in industrial production and daily use. However, if used and maintained improperly, the saw blade will wear faster, which will not only increase production costs but may also affect cutting quality and work efficiency. Therefore, it is necessary to take scientific measures to extend the service life of circular saw blades. This article will discuss in detail the selection of saw blades, correct use methods, daily maintenance, and storage and maintenance.

1. Choose the right circular saw blade

Choosing the right saw blade is the first step to extending its service life. Different materials and cutting requirements have different specifications and performance requirements for saw blades. The following aspects should be considered:

Saw blade material:

High-speed steel (HSS) saw blade: suitable for cutting soft metals, wood, etc., with general wear resistance.

Tungsten carbide (TCT) saw blade: suitable for metal, hardwood, high-density panels, etc., with good wear resistance and long service life.

Diamond (PCD) saw blade: suitable for glass, ceramics, composite materials, etc., with the highest wear resistance, but the price is more expensive.

Saw blade tooth shape:

Flat teeth (FTG): suitable for high-speed cutting of soft materials, with low durability.

Staggered teeth (ATB): suitable for wood, plywood, etc., with high cutting smoothness.

Trapezoidal teeth (TCG): suitable for hard materials such as aluminum alloy and plastic to reduce chipping.

Saw blade diameter and number of teeth:

Large diameter saw blades are suitable for cutting large materials.

High tooth number saw blades are suitable for fine cutting.

Low tooth number saw blades are suitable for fast cutting.

Correct selection of saw blades can reduce saw blade wear and improve cutting efficiency.

2. Correct use of circular saw blades

Reasonable cutting speed and feed speed:

Too high cutting speed will increase the friction and temperature of the saw blade and accelerate wear.

Too fast feed speed can easily cause saw blade tooth chipping, and too slow feed speed may cause material burning or melting.

The appropriate speed needs to be adjusted according to the hardness, thickness, and saw blade specifications of the material.

Avoid overload and dry cutting:

Excessive cutting load will cause the saw blade to deform and break.

The cutting depth should be adjusted appropriately to avoid cutting too thick materials at one time.

It is recommended to use coolant for metal materials to reduce the temperature and prevent the saw blade from annealing and softening.

Precautions for installation and use:

Before installing the saw blade, check whether the spindle and flange are clean to prevent deflection caused by unstable clamping.

Make sure the saw blade rotates in the correct direction. Reverse installation will seriously damage the saw blade.

During use, keep the machine stable to prevent vibration from affecting the cutting quality.

3. Daily maintenance and care

Cleaning the saw blade:

After use, resin, glue, metal chips, and other attachments on the saw teeth should be cleaned regularly.

You can use a special cleaner or warm water and a cleaner to soak and then clean with a brush.

Regular inspection and grinding:

Observe the wear of the saw teeth. If you find that it is blunt or notched, you should grind it in time.

Carbide saw blades can be sent to professional institutions for grinding to avoid excessive wear and tear that cannot be repaired.

If the center hole of the saw blade is worn eccentrically, check whether the flange is aligned.

Lubrication and rust prevention:

When not in use for a long time, anti-rust oil should be applied to the surface of the saw blade to prevent oxidation.

Avoid humid environment during storage, and use a moisture-proof agent or vacuum packaging.

IV. Storage and transportation

Correct storage of saw blades:

Unused saw blades should be stored in a dry and cool place, avoiding high temperatures or humidity.

Use hanging storage to prevent the saw blade from being compressed and deformed.

If it is stacked, soft pads should be placed between the saw blades to prevent damage to the teeth.

Safe transportation of saw blades:

During transportation, a protective cover or packaging box should be used to protect the saw blade.

Avoid collision between the saw blade and hard objects to prevent chipping or deformation.

The service life of a circular saw blade depends not only on its own material and quality, but also on the way it is used, daily maintenance and storage. Reasonable selection of saw blades, scientific adjustment of cutting parameters, regular cleaning, and maintenance can greatly extend the use time of saw blades, improve work efficiency and reduce use costs. I hope the suggestions provided in this article can help you better maintain your circular saw blades, maximize their performance, and bring higher profits to production.

As a professional circular saw blade seller, we provide high-quality saw blades. Through scientific selection, correct use and regular maintenance, you can extend the life of the saw blades, improve cutting efficiency, and reduce replacement costs. We also provide professional technical support to help you optimize processing results and achieve higher production benefits. If you need to purchase or consult, please contact us!

www.chinechernmachine.com

DongGuan Chine Chern Machinery Co.,Ltd.