Lipstick labeling machine manufacturer recommendation: a guide to selecting a reliable supplier

With the rapid development of the cosmetics industry, lipstick labeling machines are becoming increasingly important in production lines. Efficient and precise labeling equipment not only improves production efficiency but also ensures aesthetically pleasing and uniform product packaging, thereby enhancing brand competitiveness. However, among the numerous lipstick labeling machine manufacturers, choosing a reliable supplier is a key concern for every cosmetics company. This article will provide a comprehensive guide to choosing a lipstick labeling machine, covering the current state of the industry, equipment types, purchasing criteria, manufacturer recommendations, and after-sales service.

1. Lipstick Labeling Machine Industry Background and Development Trends

In recent years, as consumers' expectations for cosmetics appearance continue to rise, market demand for lipstick labeling machines has continued to grow. Traditional manual labeling methods are inefficient and prone to errors, making them difficult to meet the high standards of modern cosmetics production. The emergence of automated lipstick labeling machines not only addresses this issue, but also achieves high-speed and high-precision labeling operations through intelligent control systems.

Technologically, modern lipstick labeling machines are developing in the following directions:

Full Automation: Reducing manual intervention and automating the entire process from loading, labeling, and unloading.

High Precision: Utilizing servo control and photoelectric detection technologies, each lipstick is accurately and neatly labeled.

Multi-Specification Compatibility: Supports labeling of lipsticks of varying sizes and packaging materials, meeting diverse production needs.

Intelligent Control: Enhances production management through touchscreen operation, remote monitoring, and data logging.

This technological trend means that selecting a lipstick labeling machine manufacturer with advanced technology and reliable service is crucial for your company's production efficiency and product quality.

2. Main Types of Lipstick Labeling Machines

Before selecting a supplier, it's essential to understand the different types of lipstick labeling machines. Common types include:

Semi-automatic lipstick labeling machines: Suitable for small cosmetics manufacturers or those in the trial production phase. While simple to operate and low-cost, they offer limited labeling efficiency and require a high level of manual intervention.

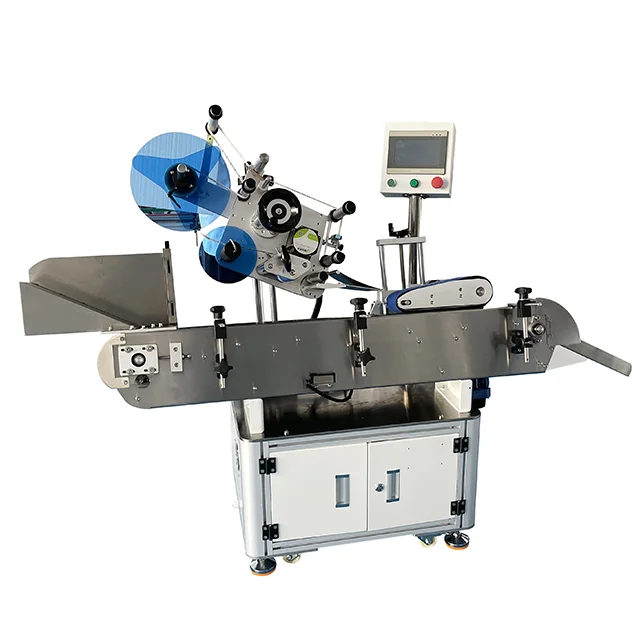

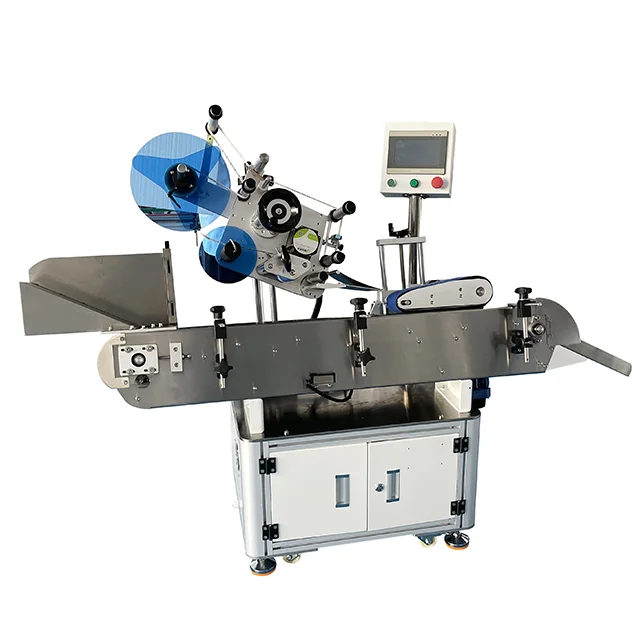

Fully-automatic lipstick labeling machines: Suitable for medium- to large-scale manufacturers. These machines automatically load, label, and reject waste, offering high throughput and stable labeling accuracy, making them the preferred choice for large-scale production.

Servo Lipstick Labeling Machine: Driven by a servo motor, it offers high labeling accuracy and is suitable for high-end lipstick brands or companies with stringent labeling requirements.

Cylinder Lipstick Labeling Machine: Designed for cylindrical lipstick tubes, it applies labels evenly and without bubbles. Some models support double-sided labeling, saving production time.

Choosing the right type of equipment based on your company's production volume, budget, and packaging specifications is key.

3. Core Criteria for Selecting a Reliable Lipstick Labeling Machine Manufacturer

When selecting a supplier, consider not only price but also equipment quality, service capabilities, and technical support. Here are a few key considerations:

3.1 Equipment Quality and Stability

Lipstick labeling machines from reliable manufacturers typically have the following features:

High-Precision Labeling: Utilizing a servo system or photoelectric detection technology ensures accurate labeling for each lipstick.

High Durability: Utilizing high-quality materials and components ensures long-term stable operation.

High Production Efficiency: Maintaining labeling accuracy even at high speeds, meeting the needs of large-scale production. 3.2 Technical Support and After-Sales Service

Labeling machines are precision equipment, so after-sales service is crucial. Reliable manufacturers typically provide:

Installation and commissioning guidance

Operational training

Troubleshooting and remote technical support

A guaranteed supply of spare parts

3.3 Customization Capabilities

Different lipstick brands vary in packaging size, material, and label material. Manufacturers that can provide customized solutions are more suitable for branded companies.

3.4 Corporate Reputation and Word of Mouth

Learn about the manufacturer's production capacity and service level through on-site inspections, industry reviews, and customer case studies. Large suppliers or those with a good reputation in the industry are often more reliable.

3.5 Price and Value for Money

While price is important, a low price does not necessarily mean high value for money. High-quality equipment with stable performance and after-sales service can save companies significant maintenance costs and production losses.

4. Recommended Lipstick Labeling Machine Manufacturers

During market research, the following types of manufacturers are worth considering:

Professional cosmetics equipment manufacturers: These manufacturers specialize in cosmetics production line equipment, possess mature technology, and offer fully automated solutions that can meet the needs of varying production scales. Automated packaging equipment manufacturers: These possess strong automation technology R&D capabilities and can provide customized labeling machines that seamlessly integrate with other production line equipment.

Small and medium-sized innovative manufacturers: These focus on cost-effectiveness and flexible customization, making them suitable for small and medium-sized enterprises or emerging brands.

When selecting a manufacturer, consider the following criteria:

Years of establishment

Technical R&D capabilities

Customer references and industry reputation

Product variety and model diversity

After-sales service network coverage

5. Considerations for Purchasing a Lipstick Labeling Machine

Clear production requirements: Before purchasing, determine your desired output based on your production plan to avoid wasting resources by purchasing equipment that is too small or too large.

Focus on equipment compatibility: Confirm whether the equipment supports existing packaging specifications and future expansion needs to ensure long-term suitability.

Test run: If possible, request an on-site test run or sample testing to verify labeling accuracy and stability.

Clear contract terms: This should include warranty period, after-sales service coverage, and parts supply guarantees to avoid subsequent disputes.

Technical training: Equipment operators must undergo systematic training to ensure stable and efficient operation. VI. Summary

Lipstick labeling machines are a crucial component of cosmetics production lines, and their quality and stability directly impact product image and business efficiency. When choosing a reliable supplier, consider not only the equipment's technical specifications but also the manufacturer's overall strength, after-sales service, customization capabilities, and industry reputation. Through scientific selection and rational procurement, companies can not only improve production efficiency but also ensure brand packaging quality and enhance market competitiveness.

If you are looking for a lipstick labeling machine manufacturer, we recommend prioritizing professional suppliers with mature technology, excellent after-sales service, and a strong reputation. Furthermore, choose the appropriate level of automation and equipment type based on your production needs to maximize production efficiency.

As a professional lipstick labeling machine supplier, Beilt leverages years of industry experience and accumulated technical expertise to provide cosmetics companies with efficient and stable labeling solutions. The company not only offers a wide range of fully automatic, high-precision lipstick labeling machines to meet diverse production volumes and packaging specifications, but also provides professional installation and commissioning, operator training, and comprehensive after-sales service. Whether for small or medium-sized cosmetics factories or large brand production lines, Beilt offers customized solutions tailored to customer needs, helping companies improve production efficiency, ensure labeling quality, and maintain their competitive edge in the fierce market.

www.beiltpack.com

beiltpack