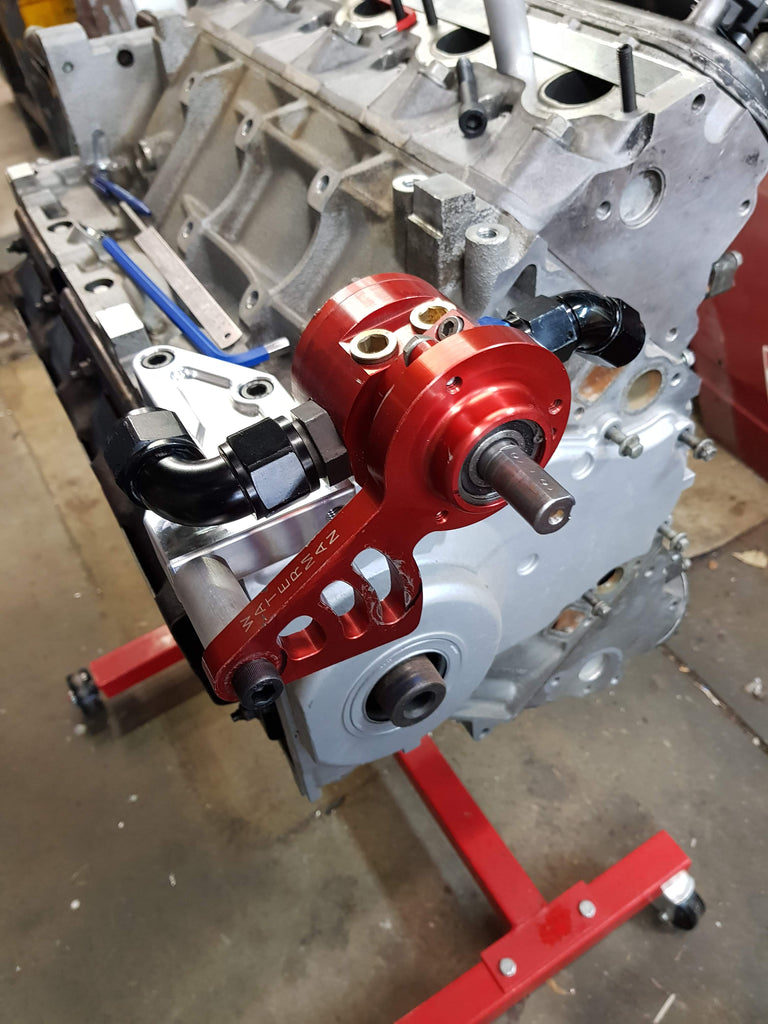

Unveiling the Inner Workings of a High Pressure Fuel Pump: A Comprehensive Guide

In the realm of automotive engineering, the high pressure fuel pump plays a pivotal role in ensuring optimal engine performance and fuel efficiency. This intricate piece of machinery is responsible for delivering fuel at high pressures to meet the demands of modern engines. In this blog post, we will delve into the inner workings of a high pressure fuel pump, exploring its components, functions, and the intricate processes that enable it to deliver fuel with precision and efficiency.

- Understanding the Purpose of a High Pressure Fuel Pump:

Before delving into the inner workings, it is crucial to comprehend the purpose of a high pressure fuel pump. Unlike conventional fuel pumps, which operate at lower pressures, high pressure fuel pumps are designed to deliver fuel at significantly higher pressures, typically ranging from 500 to 2000 bar. This increased pressure ensures efficient atomization and combustion, resulting in improved engine performance and reduced emissions. - Components of a High Pressure Fuel Pump:

A high pressure fuel pump consists of several key components, each playing a vital role in its overall functionality. These components include:

- Camshaft: The camshaft is responsible for driving the pump's pistons, controlling the fuel delivery process.

- Pistons: The pistons create the necessary pressure by compressing the fuel within the pump.

- Plunger: The plunger is a crucial component that moves back and forth, drawing in fuel and then compressing it to generate high pressure.

- Fuel Inlet and Outlet Valves: These valves regulate the flow of fuel into and out of the pump, ensuring precise control over the fuel delivery process.

- The Fuel Delivery Process:

The fuel delivery process in a high pressure fuel pump involves several intricate steps, each contributing to the overall efficiency and performance. These steps include:

- Fuel Intake: The pump draws fuel from the fuel tank through the fuel inlet valve.

- Fuel Compression: As the plunger moves forward, it compresses the fuel, increasing its pressure significantly.

- Fuel Injection: Once the desired pressure is achieved, the fuel outlet valve opens, allowing the pressurized fuel to be injected into the engine's combustion chamber.

- Fuel Regulation: The pump continuously adjusts the fuel pressure based on the engine's requirements, ensuring optimal performance under varying conditions.

- Advanced Technologies and Innovations:

In recent years, advancements in high pressure fuel pump technology have revolutionized the automotive industry. These innovations include:

- Direct Injection Systems: High pressure fuel pumps are an integral part of direct injection systems, which offer improved fuel efficiency, reduced emissions, and enhanced engine performance.

- Variable Displacement Pumps: Variable displacement pumps adjust the fuel delivery rate based on the engine's demands, optimizing fuel consumption and reducing unnecessary energy consumption.

Conclusion:

The high pressure fuel pump is a critical component in modern engines, ensuring efficient fuel delivery and optimal engine performance. Understanding its inner workings, from the components to the fuel delivery process, provides valuable insights into the complexities of automotive engineering. By embracing advanced technologies and innovations, high pressure fuel pumps continue to evolve, driving the automotive industry towards a more sustainable and efficient future.