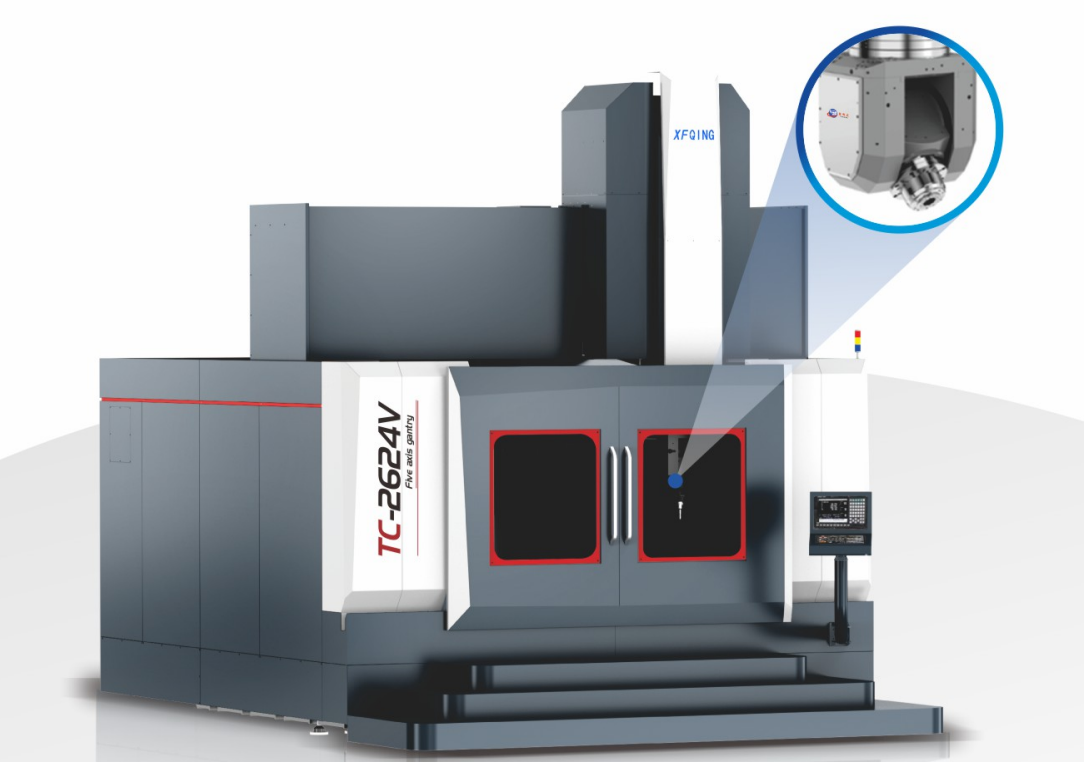

Top Industrial Applications of Five-Axis Crane Gantry Systems

In today’s advanced manufacturing landscape, precision, flexibility, and automation are no longer optional—they are essential. One of the most significant advancements in industrial automation is the five-axis crane gantry system, a powerful solution designed to handle heavy workpieces with multidirectional movement and micron-level positioning accuracy.

As a leading manufacturer and supplier of CNC machining centers, wire EDM machines, EDM die-sinking machines, milling machines, and related equipment, Zhiquan Electromechanical Equipment Co., Ltd. is proud to provide industrial automation systems that align with modern manufacturing demands. Among these, five-axis crane gantry systems have become a cornerstone in a variety of precision-driven industries.

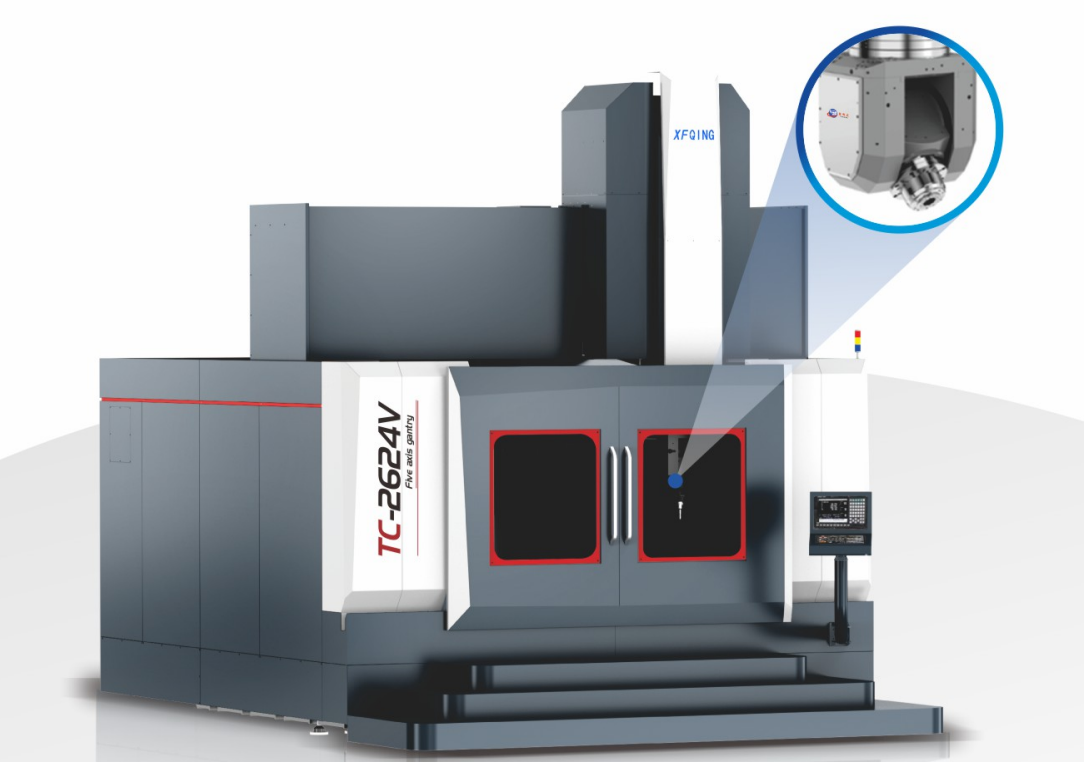

What Is a Five-Axis Crane Gantry System?

A five-axis crane gantry system is a high-precision, large-format overhead robotic system capable of moving loads in X, Y, Z, A, and B axes. It is often mounted over large work areas and enables tools or manipulators to access hard-to-reach angles while maintaining consistent positioning and stability.

Unlike traditional gantry systems with limited directional control, five-axis systems add rotational axes, allowing for more complex and flexible operations in vertical and horizontal planes. This capability is particularly beneficial in industries requiring heavy-duty handling, high repeatability, and exact alignment.

Top Industrial Applications

1. Aerospace Component Manufacturing

In aerospace, parts such as engine housings, landing gear frames, and wing spars often involve complex geometries and tight tolerances. A five-axis gantry system allows precise material handling and positioning for multi-angle machining and assembly, critical for performance and safety.

Zhiquan’s Advantage: Zhiquan’s integration of five-axis gantry systems with high-speed CNC machining centers ensures seamless coordination for heavy aerospace workpieces.

2. Automotive Die and Mold Processing

Automotive molds, including injection mold bases, press dies, and body panel dies, require intricate detailing on large and heavy parts. A five-axis crane gantry can position dies with precision for EDM or CNC operations without manual repositioning.

Zhiquan’s Equipment Synergy: When used alongside Zhiquan’s EDM die-sinking machines, these gantries improve workflow efficiency and reduce alignment errors.

3. Heavy Machinery Assembly

Manufacturing and assembling mining equipment, agricultural machines, and industrial turbines involves lifting and aligning oversized components. A five-axis gantry allows for safe, precise handling during both machining and final assembly stages.

4. Tool and Mold Workshops

Mold workshops that handle diverse product lines need flexible equipment. Five-axis gantry systems help manipulate large tool sets, support multi-machine integration, and reduce labor-intensive repositioning.

Zhiquan in Action: Workshops using Zhiquan’s CNC centers and milling machines benefit from synchronized material transfer using overhead gantries.

5. Wind Power and Renewable Energy

Components like rotor hubs, generator housings, and nacelle bases require precise machining and inspection. A five-axis gantry system ensures correct positioning for both processing and quality control, especially in large-scale clean energy projects.

6. Shipbuilding and Marine Engineering

Fabricating and assembling ship parts such as propeller shafts, rudder systems, and engine blocks involves massive structures. Gantry systems provide multidirectional positioning, helping engineers work on various faces of a structure with one setup.

7. Rail and Transport Equipment Manufacturing

Manufacturing railcar components, such as bogie frames, axle housings, and aluminum car bodies, demands exact alignment. Five-axis gantries simplify positioning over long production lines and assist in integrating welding and inspection tools.

Benefits of Using Five-Axis Gantry Systems

Precision Handling: Micron-level positioning reduces errors in high-tolerance applications.

Space Optimization: Mounted overhead, gantries free up floor space for other equipment.

Automation Integration: Seamlessly integrates with CNC machines, EDMs, and inspection systems.

Improved Safety: Minimizes manual lifting and handling of heavy or awkward components.

Cost-Efficiency: Reduces cycle times and manpower requirements in large-format processing.

Why Choose Zhiquan Electromechanical Equipment Co., Ltd ?

With a reputation built on quality engineering and customer-focused solutions, Zhiquan Electromechanical Equipment Co., Ltd. delivers robust, precise, and fully integrated systems for modern industrial workshops. Zhiquan's five-axis gantry systems are developed to work hand-in-hand with its CNC, EDM, and milling machines, providing clients with end-to-end solutions in smart manufacturing.

✔ Proven manufacturing experience

✔ Customizable automation solutions

✔ Full technical support and training

✔ Strict quality control and CE-certified equipment

Conclusion

The versatility and precision of five-axis crane gantry systems have revolutionized operations in industries that demand complex handling and processing of large components. With cutting-edge solutions from Zhiquan Electromechanical Equipment Co., Ltd., manufacturers can streamline their production, increase safety, and reduce downtime while meeting the highest standards of accuracy and efficiency.

Five-Axis Machining Centers Explained: From Basic Functions to Complex Applications

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.