The Future of Manufacturing: Exploring the Advantages and Challenges of Polypropylene 3D Printing

Polypropylene (PP) is a thermoplastic polymer that is widely used in various industries due to its excellent chemical resistance, high melting point, and low density. With the advent of 3D printing technology, PP has become a popular material for additive manufacturing. In this article, we will explore what polypropylene 3D printing is, its benefits, applications, and challenges.

What is Polypropylene 3D Printing?

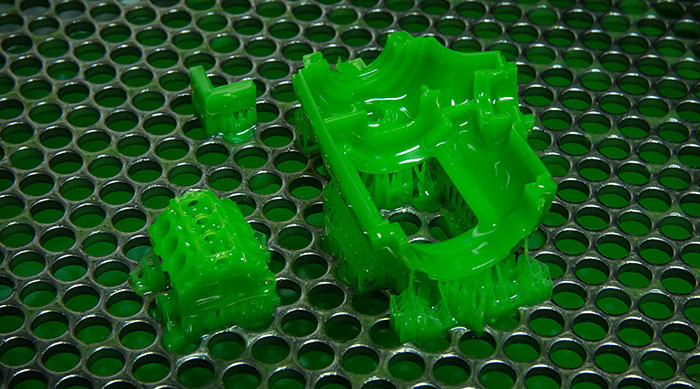

Polypropylene 3D printing is the process of using a 3D printer to create objects from polypropylene material. The process involves melting the PP filament and extruding it through a nozzle to create a three-dimensional object layer by layer. PP 3D printing is a relatively new technology, but it has gained popularity due to the unique properties of polypropylene.

Benefits of Polypropylene 3D Printing

Polypropylene 3D printing offers several benefits over traditional manufacturing methods. One of the main advantages is the ability to create complex geometries that are difficult or impossible to produce with traditional methods. PP 3D printing also allows for rapid prototyping, which can save time and money in the product development process. Additionally, PP is a lightweight material, making it ideal for applications where weight is a concern.

Applications of Polypropylene 3D Printing

Polypropylene 3D printing has a wide range of applications in various industries. In the automotive industry, PP 3D printing is used to create lightweight parts such as air ducts, engine covers, and interior components. In the medical industry, PP 3D printing is used to create surgical instruments, prosthetics, and medical devices. PP 3D printing is also used in the packaging industry to create custom packaging solutions.

Challenges of Polypropylene 3D Printing

Despite its many benefits, polypropylene 3D printing also presents some challenges. One of the main challenges is the difficulty in achieving good adhesion between layers. PP has a low surface energy, which makes it difficult for layers to bond together. Another challenge is the warping of the material during the printing process. PP has a high shrinkage rate, which can cause the material to warp and deform during printing.

Conclusion

Polypropylene 3D printing is a promising technology that offers many benefits over traditional manufacturing methods. Its unique properties make it ideal for a wide range of applications in various industries. However, there are also some challenges that need to be addressed to fully realize the potential of PP 3D printing. With further research and development, polypropylene 3D printing is poised to revolutionize the manufacturing industry.